|

|

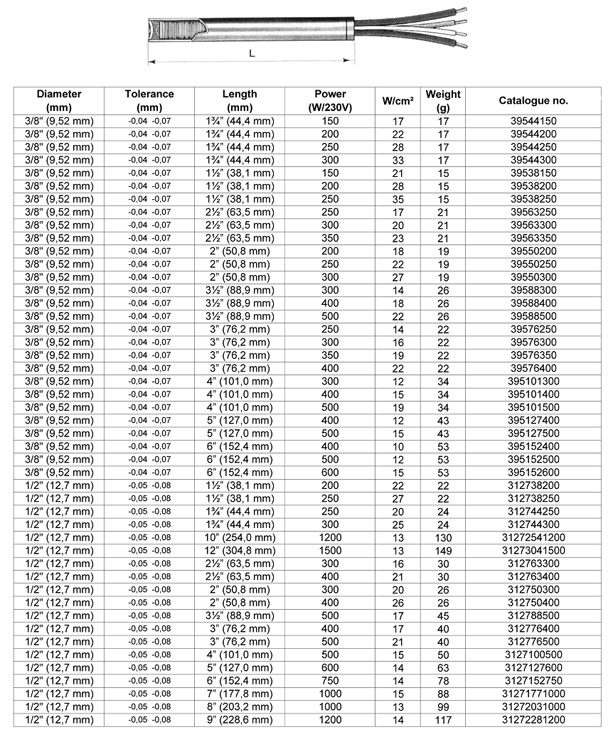

ULTRAMAX are a new generation of high wattage electric heating elements, having high power in a limited area and ensuring, all the same, excellent reliability under heavy-duty working conditions. The special technology used in their construction make them the most advanced type of heating element. |

|

The nickel chrome wire wrapped around a magnesium oxide core is situated in a peripheral position, with a very thin compressed insulating layer between wire and sheath. This allows efhcacious heat exchange, thus maintaining the temperature of the resistance wire at a much lower level compared to other heating elements where the wire is situated in the center.

Furthermore, not only do they owe total reliability to the use of advanced technology and precise inspection techniques during manufacture, but also to the use of Hrst-class material from the best sources on the market. |

|

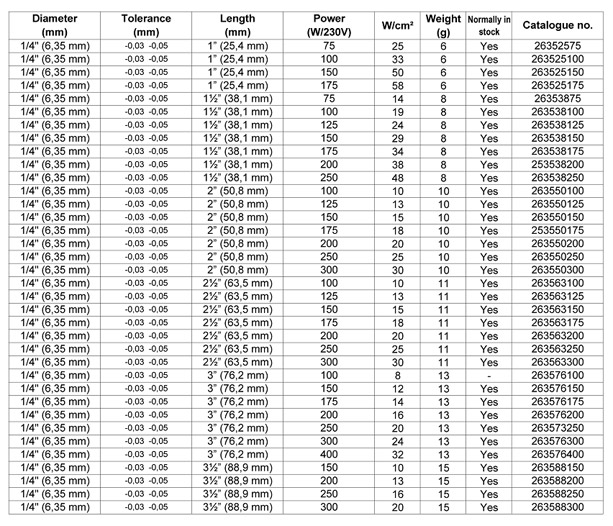

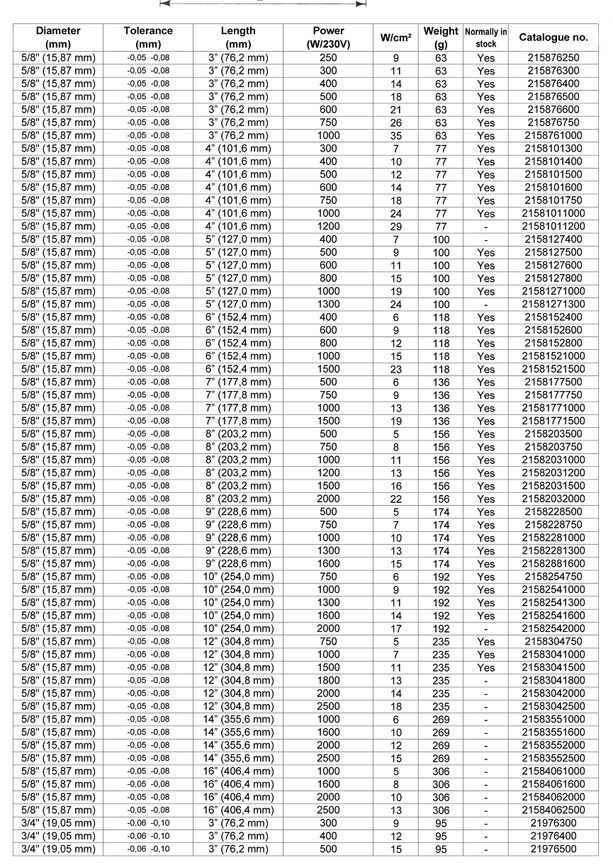

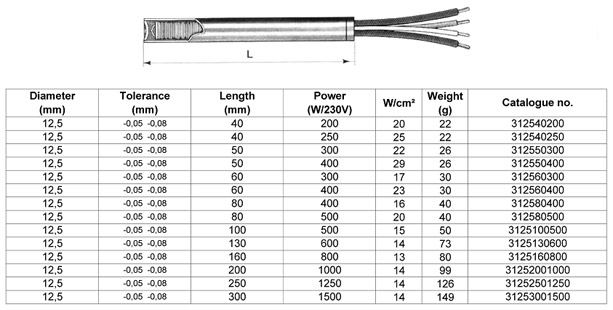

Standard U LTRAIVIAX, Imperial Sizes |

|

Unheatad length is 5 mm from bottom end and 10 mm from cable end. See tolerances further down. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Standard TolerancesDIAMETER: See charts above. Technical RecommendationsDistribute the required load over the highest possible number of heaters in order to reduce the density in W/cm2 of each heater. Insert the ULTRAMAX cartridges in bored holes. Clearance between heater and hole reduces heat transmission, increases cartridge temperature, intensities the oxidation process, increases energy consumption and considerably decreases heater life. lf the cartridges are mounted on moving parts of the machine, make sure the cables are well anchored a few centimeters upstream of the heater's outlet to prevent movements that could result in break-downs. Even though small movements are generally acceptable, there is always a high risk of break-downs. It is advisable to make a few extra turns of the cable upstream of the outlet to lengthen its lite. If the application requires continuous movement, it is indispensable to advise Rottil with the width and type of motion. In many cases an intermediate box is very useful for transferring motion to an additional cable that can easily be replaced. lf there are a significant number of vibrations, it is advisable to use an intermediate connection box as described above. Protect cables and cartridge head, especially if not sealed, against contamination from oits, liquids, sprays. corrosive gases, splashes of water. With repeated hotfcold cycles, the cartridge absorbs any substance that comes into contact with the insulating material. lvlost substances char and produce short circuits. The only sealant that ensures total protection is SCA-DD. lf the cables stay in areas with a constant temperature above 25D°C, one ofthe following actions becomes indispensable: Prevent the cartridge head, and consequently the cables, from entering the hole. The heat of the metal ground could damage the insulating material and the sealant. Avoid using adhesive tape near the cartridge head. The adhesive of certain types of tape could enter the head, char and produce short circuits. If taping is unavoidable. use si|icone-base adhesives. At high temperatures it is always advisable to thermally insulate the heated parts. The following positive effects are obtained by

insulation: To improve heat conductivity and ease the extraction of the cartridge, use our LUBRIHOT compound. Make sure the compound does not dirty the cartridge head as this could result in electricity leakage or short circuits. Place the external thermocouples no further than 10 mm from the cartridge and, if possible, in the central area. This waming is extremely important when the cartridge has a high watt density. The use of proportional microprocessor thermoregulators is essential for extending heaters lite. Oxidation of ULTRAMAX heaters and the hole in which they are inserted, produced by many hours of work at high temperatures, can make it difficult to extract the burnt element. After having attempted extraction by using EXTRACTOR, make a hole with a bit D,2-0,3 mm smaller than the nominal diameter of the heater. After extraction, use a boring machine to re- bore the hole, if necessary, use an iron rod and a hammer as well. A ROTFIL cartridge heater, if used correctly, provides a very long life. To obtain maximum performance, advise Rotfil with all the details that might be important in order to determine the most suitable heater. |

|

Heating of LiquidsThe compactness and high watt density of Ultramax heaters make it an excellent solution for the heating of liquids. Make sure the heater is always covered with at least 20 mm of liquid. To avoid emptying the tank when replacing the used heater. is advisable to use our additional sheaths. Do not exceed the densities iri Wfcmg suggested in the following table. Shall there be forced re-circulation, the density can be slightly higher. A lower density, on the other side, increases the heater’s life. |

|

|

|

Heating of MetalsThe chart below shows maximum admissible clearance in millimeters between hole and ULTRAMAX cartridge as a function of the density in Wfcm2 and the working temperature. For aluminum and brass, choose the clearance in the column corresponding to the temperature immediately superior to that of the working temperature (+100°C). The clearance is obtained by the difference between the hole diameter and the real diameter ofthe cartridge (nominal diameter-maximum tolerance). Example: Hole diameter 12,5 mm; nominal diameter of cartridge 12,5 mm. 12.6 mm -12.42 mm (12.5 -Cl.08 max. catalog tolerance) = 0.18 mm (max. admissible clearance) For optimum working conditions, energy-saving and longer heater life, it is advisable to bore holes with a tolerance of H7. |

|

|

|

Operating TemperaturesSheath temperature, depending cm power density and media: |

|

Maximum power density of Ultremex heaters in high-temperature environments: |

|

|

|

UItramax with ThermocoupleAny type of ULTRAMAX heater can be manufactured with a built-in thermccciuple, and a big stock of finished heaters is kept, ready for prompt shipment. THERMOCOUPLE TYPES: |

|

|

|

THERMOOOUPLE POSITIONS:UTC Type 1 |

|

|

|

UTC Type 2 (standard) |

|

|

|

UTC Type 3 |

|

|

|

UTC Type 4 |

|

|

|

OPTIMAL USE OF ULTRAMAX HEATERS WITH THERMOCOUPLE:As shown in the drawing above, in heaters with thermocouple UTC 1 and UTC 2 the sensing join of the thermocouple is located at one end of the cartridge, sensibly colder than the body of the cartridge. This causes the thermocouple to sense heat with a certain delay to its production in the heating core of the cartridge. Therefore, if the heater is controlled by an electronic thermoregulator, great care must be put in setting its switching temperature to avoid burning the heater just because the thermocouple is exposed to heat much later than the central body of the heater. lf the heater is in free air (or in a small metal body with more than 10 W/cm2), it is advisable that the limit temperature is set (at start-up) at values increasing by intervals of, say, 100°C (example: 80°C, 180°C, 2BO°C, etc., till desired value), with a necessary resting time before re-switching-on at each increase of the limit value. This because of the rislc of the heater's burning before the thermoregulator switching off (for example, the body could go over 1000°C before the thermocouple reaches 500°C). lf the heater is inserted in a greater metallic body, in a hole honed to H7 tolerance, it is possible to directly set the thermoregulator at the target working temperature straight from start-up. With UTC 3 and UTC 4 heaters the above precautions are normally not necessary. It the temperature control has a sort-start function, the above precautions can be reduced, nonetheless, trial cycles are always advisable. |

|

Standard Ultramax with Thermocouple, Metric SizesStandard version is with Fe-Co (Type J) thermocouple, position UTC Type 2, with 1000-mm cables. All the models listed below are normally kept ln stock. |

|

|

|

|

|

Standard Ultramax with Thermocouple, Imperial SizesStandard version is with Fe-Co (Type J) thermocouple, position UTC Type 2, with 1000-mm cables. All the models listed below are normally kept ln stock. |

|

|

|

Standard Ultramax with Thermocouple, Metric SizesStandard version is with Fe-Co (Type J) thermocouple, position UTC Type 2, with 1000-mm cables. All the models listed below are normally kept ln stock. |

|

|

|

|

|

|