|

|

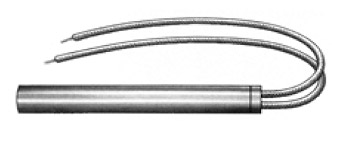

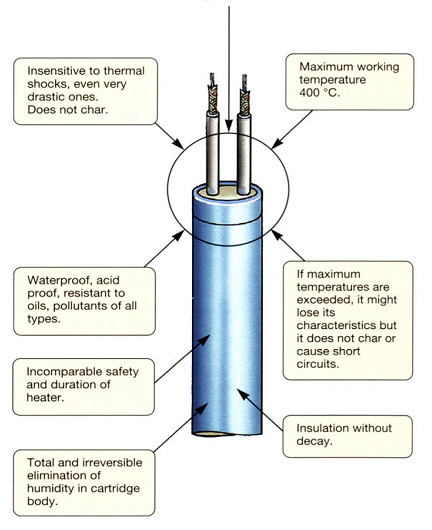

ULTRAMAX are a new generation of high wattage electric heating elements, having high power in a limited area and ensuring, all the same, excellent reliability under heavy-duty working conditions. The special technology used in their construction make them the most advanced type of heating element. |

|

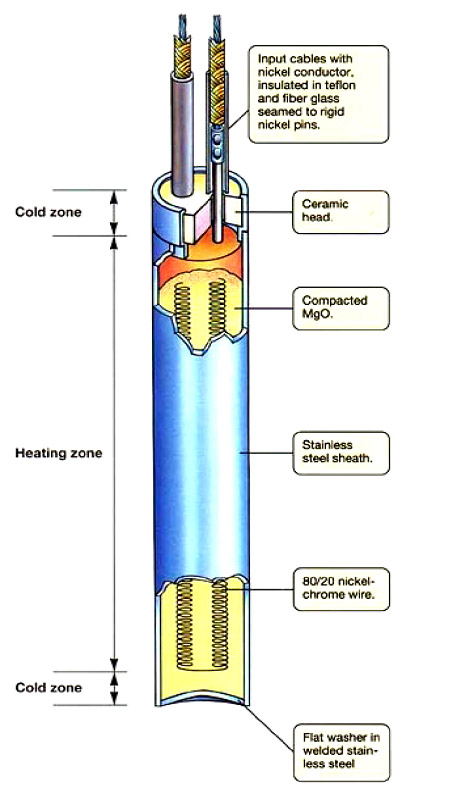

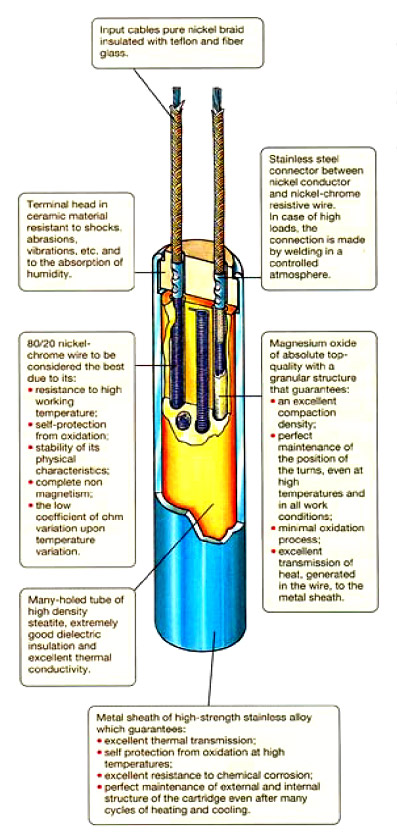

The nickel chrome wire wrapped around a magnesium oxide core is situated in a peripheral position, with a very thin compressed insulating layer between wire and sheath. This allows efhcacious heat exchange, thus maintaining the temperature of the resistance wire at a much lower level compared to other heating elements where the wire is situated in the center.

Furthermore, not only do they owe total reliability to the use of advanced technology and precise inspection techniques during manufacture, but also to the use of Hrst-class material from the best sources on the market. |

|

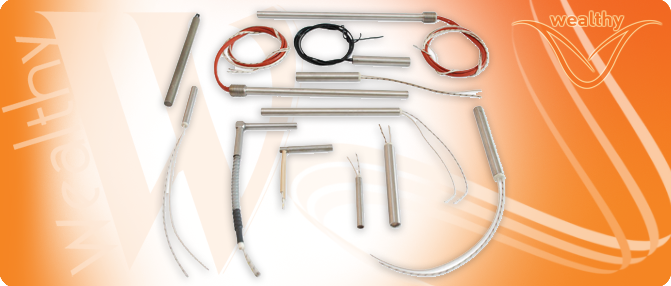

Cable Options |

|

S1 ULTRAMAX WITH FLEXIBLE CABLES ULTRAMAX heaters can be supplied with flexible cables coming directly out of the cartridge. These are suitable when a highly flexible cable is required also near the head. With this solution, the cartridge head must riot exceed the temperature of 260 °C. For higher temperatures, contact our Customer Service. |

|

|

|

|

S2 ULTRAMAX WITH CABLES PROTECTED BY FLEXIBLE TUBE ULTRAIVIAX cartridges can be supplied with cables protected by a flexible tube of galvanized steel (standard version), or stainless steel (ori request). This type of protection is advisable to avoid the cable being smashed. grazed or torn. |

|

|

|

| S3 ULTRAIIIIAX WITH CABLES PROTECTED BY FLEXIBLE METAL BRAID ULTRAMAX cartridges can be supplied with the cable protected by a flexible metallic braid, in galvanized steel in the standard version, in the stainless steel braid upon request. This type of protection is advisable for protecting the cable from operations and tears while maintaining excellent flexibility. |

|

|

|

S4 ULTRAIIIIAX WITH SOLID NICKEL WIRES ULTRANIAX cartridges can be supplied with solid nickel wires, either naked or insulated by a silicone sheath, silicone glass, tetion, or ceramic beads.This solution is useful when, for assembly purposes or mechanical needs, the input wires need to be particularly rigid. |

|

|

|

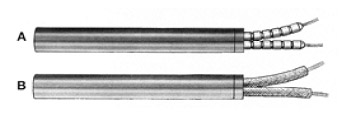

| S5 ULTRAMAX WITH INSULATED CABLES FOR HIGH TEMPERATURES ULTRAMAX cartridges can be supplied with nickel cables insulated with ceramic beads (A), or with ceramic Hber(B). One of these solutions is indispensable when the cables are in areas with constant temperatures above 250 °C. |

|

|

|

S6 ULTRAMAX WITH CABLES PROTECTED BY CORRUGATED (LIOUID-PROOF) FLEXIBLE TUBE ULTRAMAX cartridges can be supplied with cables protected by corrugated tlexible tube with continuous wall of stainless steel welded to the cartridge sheath. This solution is indispensable when the cables are exposed to liquids. corrosive gases, dangerous areas, etc. |

|

|

|

S7 SEALED ULTRAMAX ULTRANIAX cartridges can be supplied completely sealed. Due to the hygroscopicity insulating ceramic material. our ULTRAMAX cartridges can easily absorb atmospheric humidity and thus decrease their electrical insulation. Though this can be avoided with a short period of pre-heating, to solve once and for all the problems, ULTRAMAX cartridges must be sealed -with resins or silicones when head temperature is below 250 °C; with our patented SC 400 system when the temperature is over 260 °C (see page 22). Sealing is indispensable when the cartridge head might be exposed to washing, oil leaks, corrosive gases, etc. |

|

|

|

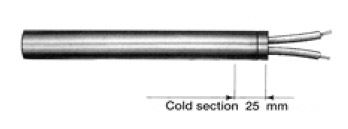

90° - Cable Outlets |

|

|

|

Pins and Fast-OnsS13 |

|

|

|

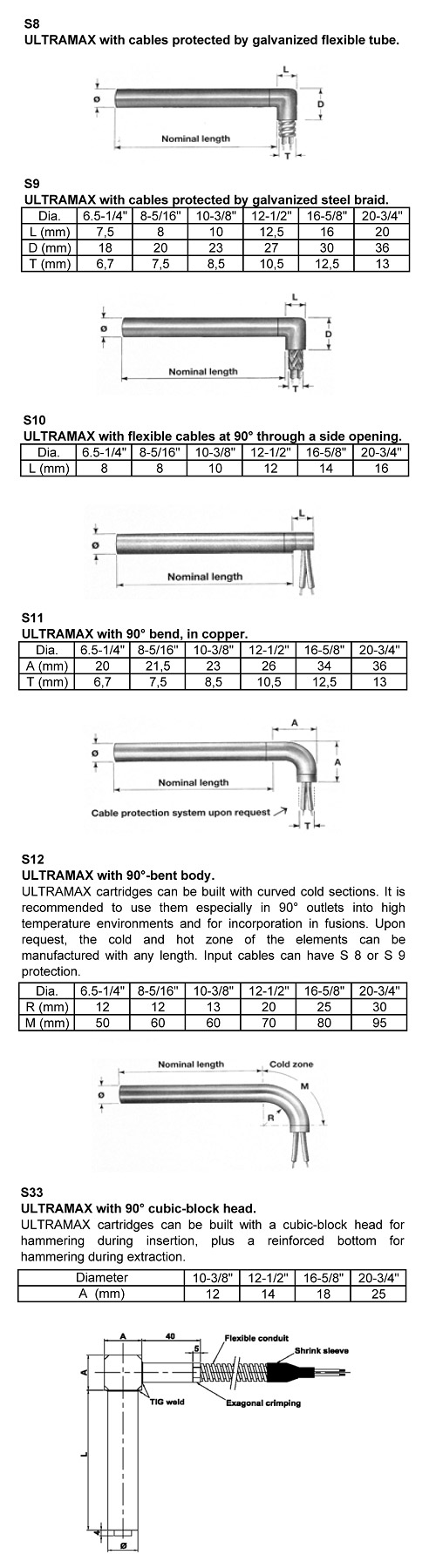

S14 ULTRAMAX WITH FAST-ON CONNECTORS ULTRAMAX cartridges with a diameter over 14 mm can be supplied with faston connectors, solidly built into the cartridge head. |

|

|

|

|

|

|

|

|

|

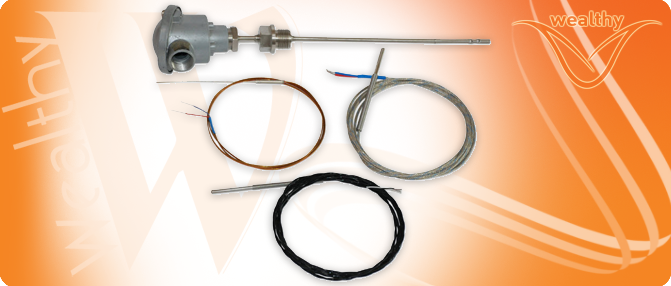

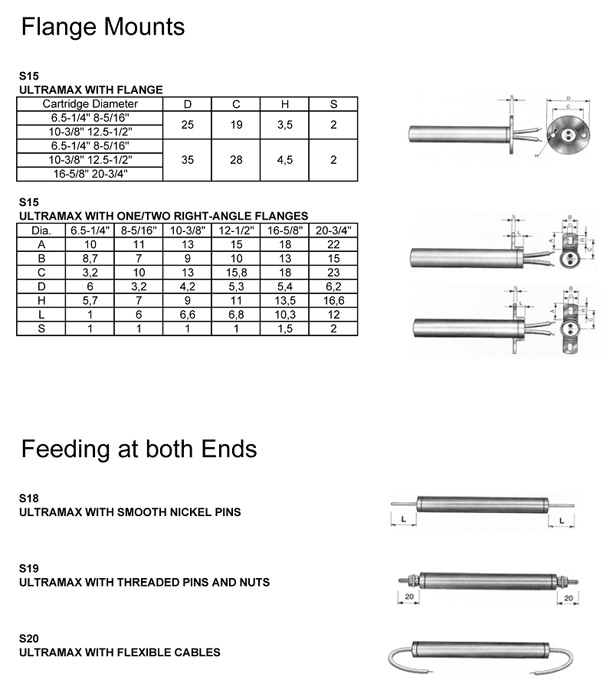

High-Temperature Sealing SC 400 is a seating against humidity, compatible with high temperatures. |

|

|

|

The magnesium oxide in the core of all high-power density cartridge heaters is an excellent electrical insulator and a good heat conductor. However, it has a high hygroscoprc characteristic, therefore heaters that are not “turned on" and are in a humid environment tend to lower their level of lnsulation, which sometimes can cause safety devices to intervene at start-up ln the worst cases the heaters might get irreversibly damaged by short circuit. If the temperature of the heater’s head does not exoeed 260"C, the head sealing can be made in resins or silicone, but for higher temperatures or higher safety ratios, other solutions are required. Rotfil found and patented the solution to this problem; SC400 is a perfect sealant against humidity, irreversible, resistant to high pressures and continuous high temperatures of up to 400 °C. It does not change its structure or characteristics in the years, it is resistant to water, acids, air pollution, and does not char. lt is not immersion proof. SC 400 is an inorganic compound that is fused into the heater’s head in a contro|led-cyc|e process, thus forming a cohesive seal adherent to the metal surfaces at molecular level. lt totally protects all internal components from pollution and oxidation, increasing the life of the heater, The use of ULTRAMAX SC 400 cartridges is indispensable everytime you need a high safety level and high reliability Typical application Helds include medical and surgical equipment, aerospace, nuclear-energy, military |

|

TOTALLY SEALED AGAINST HUIVIIDITY even with high temperatures |

|

|

|

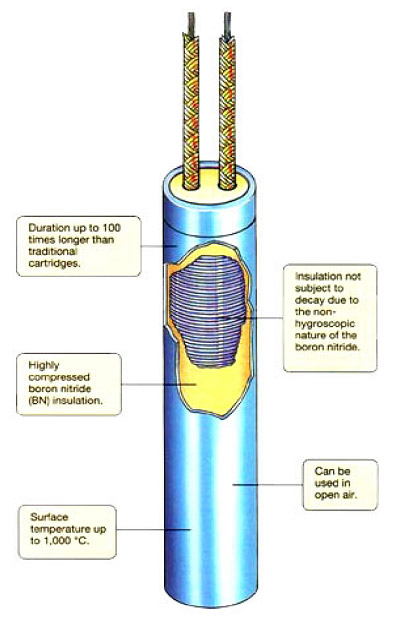

IPERIVIAX Extra-High Density Cartridge Heaters IPERMAX extra-high density cartridge heaters are a product of Rotfi|’s research laboratories. Such technology allows high compression ratios even on Iow-density insulating powders such as boron nitride (BN), obtaining a product similar to ULTRAMAX cartridges but much superior in performance. IPERMAX cartridge heaters are the best heaters under all following aspects: -High Watt density reached It is recommended to use these heaters not only when the work conditions required are incompatible with other types of heaters but also when there is the need to use an extremely reliable heater. Particularly suitable for applications in the aerospace, medical, military industry, or in high-output fully-automated plants with high downtime costs. Due to its very special construction technology, IPERIVIAX cartridges are currently manufactured only in diameters; 12.5 -14 -16 mm. Ask our Customer Service for other sizes. |

|

|

|

SUPERIVIAX Middle Density Cartridge Heaters Supermax cartridge heaters are recommended wherever the performance of Ultramax cartridges is not fully USAGE RECOMMENDATIONS If holes are manufactured with a considerable clearanoe or a high watt density is used, or in any case in which the application is demanding, we advise one ofthe following: - A higher number of heaters can be used, therefore with lower watt density and heat exchange. |

|

|

|

APPLICATIONS SPECIAL FEATURES |

|

|

|

NORIVIAX Low Density Cartridge Heaters Normax heating cartridges are made of three elements: an 80/20 nicke|-chrome heating wire spiral, studied for the desired watt density, inserted in a ceramic insulator that resists well to temperature variations and bears good thermal conductivity, all contained in a gauged stainless steel tube. The ceramic insulatlon consists in a mass of powder magnesium oxide, with a physical structure and particle dimensions that allow: - excellent density and compactness The heater is fed by pure nickel flexible cables, insulated with PTFE and fiberglass APPLICATIONS SPECIAL FEATURES |

|

|

|

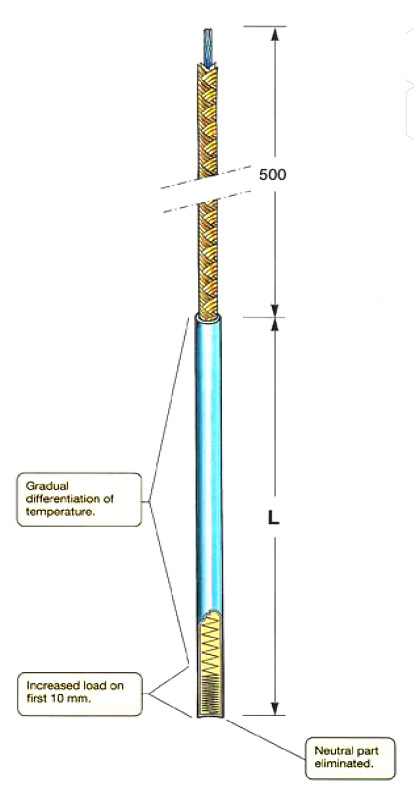

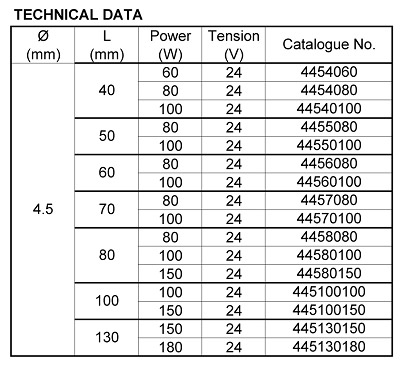

MICROMAX Low Voltage Cartridge Heaters Micromax cartridge heaters are exclusively designed for low-voltage supply (48 V or less). One of the two poles of the resistance wire is welded to the metal sheath, therefore supply voltage is fed to the ground and to the insulated cable, Micromax heater applications include use in vehicles (industrial vehicles, caravans, boats, etc.), as well as in the heating of injection nozzles for plastics, at a supply voltage of 24 V, due to their being easy to install, small and resistant Please check Mrcromax standard sizes and technical data. Some of the most important features include |

|

|

|

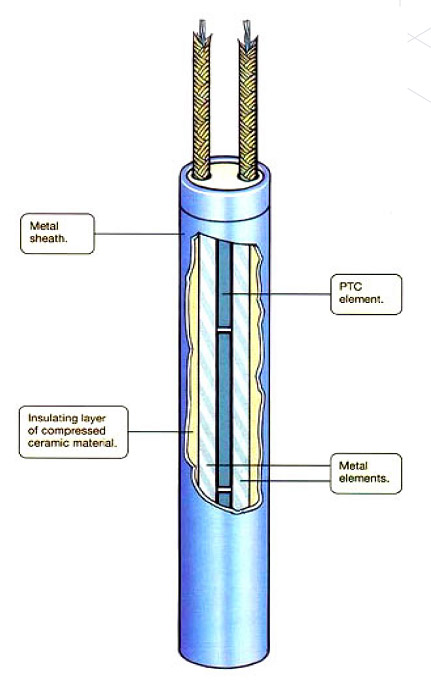

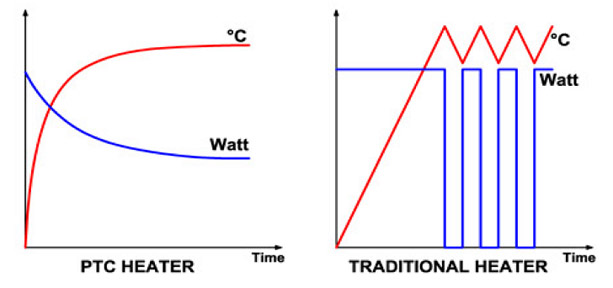

AUTOIVIAX Self-Limiting PTC Cartridge Heaters PTC elements are electronic components made of a polycrystalline ceramic material with a barium titanate base, suitably doped according to the desired work characteristics. Its peculiar property is instantly rising its resistance in a logarithmic ratio when temperature rises. This process, practically instantaneous, reaches stability at a certain temperature (Curie point). At such temperature the only energy absorbed is the one needed to keep the PTC elements temperature constant. Therefore, a rather high energy absorption will occur initially, that will then decrease depending, after a while, only on the dissipation coefficient. PTC is indeed the acronym of "Posrtive Temperature Coefficient". Automax cartridges incorporate PTC elements, thus cannot be classihed with a fixed wattage absorption. Their most significant measurable feature is instead the temperature that the heater`s sheath reaches when the cartridge is powered at the specified voltage and placed in open air at ambient temperature. The input voltage of Automax cartridges can vary within a considerably broad range (12-36 V and 110-240 V) without significant variations in their efficiency. In Automax cartridges, PTC lend their properties to the whole heater according to a technology exclusively The main advantages of Automax heaters’ performances are therefore: -Self-regulation |

|

|

|

|

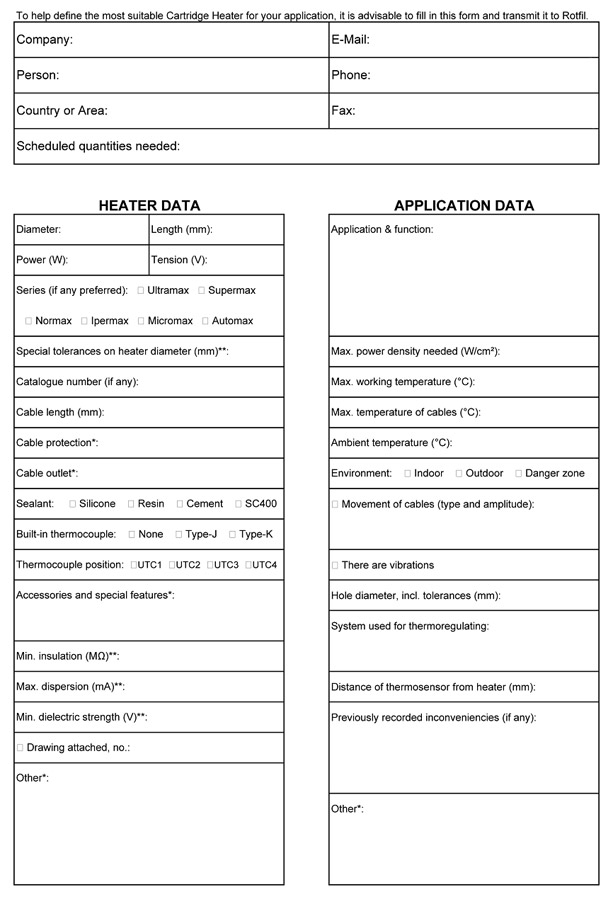

Enquiry Form for Cartridge Heaters |

|

|

|

| *: Please, consult all catalogue-listed configurations (for example cable and outlet options). *: Please, Hll-in only if your application needs a value that differs from catalogue standard. |

|

|

|

|